Dana Smith oversees the Eagen Post Office’s customer service.

“When the carriers come in the morning, they grab their packages,” said Smith. “[They] get all their other mail ready and then leave through that door.”

The hundreds of letters Bernie will deliver that day were already sorted the night before.

A 90-acre mail processing plant a few miles away in St. Paul runs 24 hours per day, seven days a week.

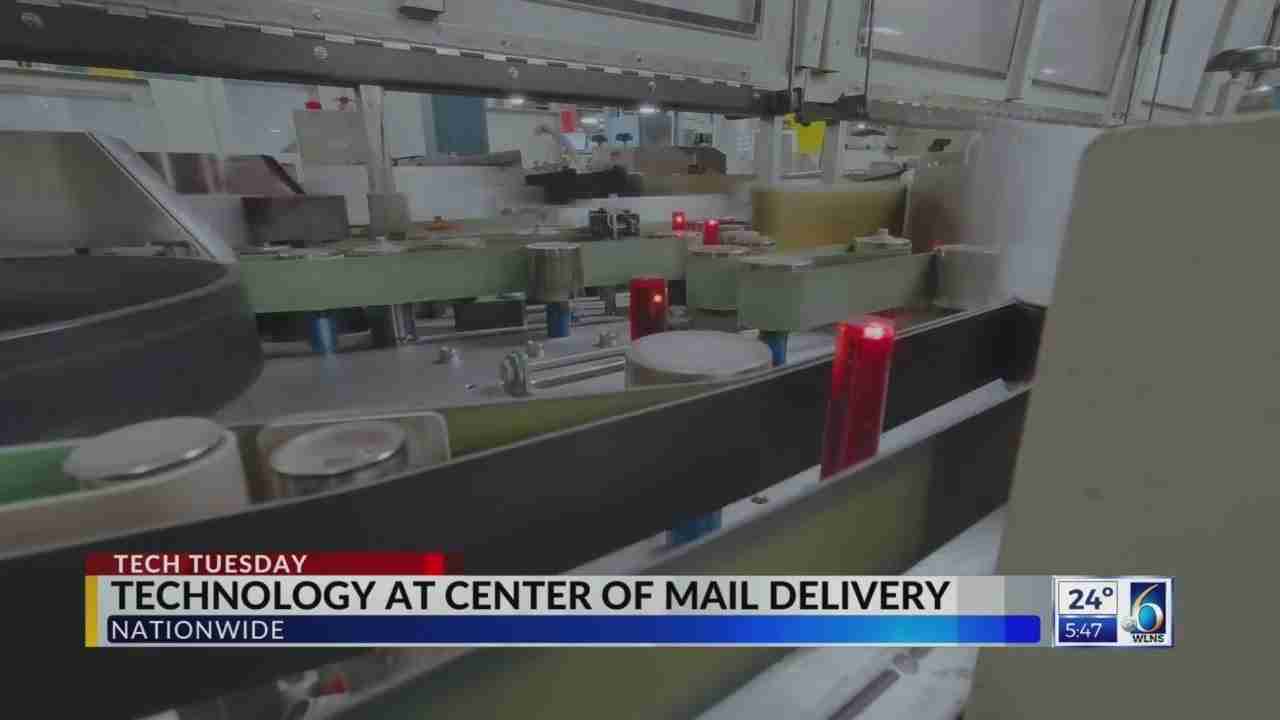

First, they flatten the pieces of mail that come from the trucks to the conveyer belt so they can be fed into this machine.

The machine also sprays an orange ID tag and then will spray in black a bar code that holds all the address’s information.

The machine sorts the letters by location into 12 different bins.

Those bins are then brought to other machines, which sort by zip code and finally individual address.

This means the letters are now all in the right order for the carrier’s route.

At the same time, from above, the bar codes on packages are being scanned too.

Each bin equates to one post office, and typically runs until 3:45 a.m., so that mail carriers like Schroeder can make a timely delivery.